Metro St. Louis

Products

Vontas OnRoute

“We’ve had dramatic reductions in cost and reduced road calls, since we changed to a predictive maintenance model.”

Darren Curry,

Chief Mechanical Officer, Metro Transit – St. Louis

Metro Transit – St. Louis transitioned from a break fix maintenance model to a predictive replacement maintenance model resulting in $2.4 million in annual savings on their operational budget.

Background

Metro Transit – St. Louis services more than 140,000 riders daily. Despite funding staying stagnant or declining, ridership has increased 18 percent over a five-year period. In order to continue to provide efficient, cost-effective service, Metro Transit needed to better forecast its asset lifecycle and predict outcomes rather than act reactively.

Challenges

Metro Transit’s break fix, or “reactive” maintenance program, resulted in excessive road calls, disruptions to service, inaccurate asset management and high costs due to the time required to manually inspect assets to find the causes of failure. They also were forced to rely on guesswork to determine things such as miles driven on the heaviest duty cycle for each asset. Their existing solution did not allow them to forecast parts that would be needed in the future. They were looking for a way to proactively keep equipment in top shape, prevent accidents from asset failure, improve passenger experience and reduce operating costs for the agency.

Solutions

Metro Transit adopted a predictive replacement maintenance program. By implementing the Vontas Vehicle Intelligence solution, they are able to use business intelligence data gathered from the vehicles and the controller area network to proactively manage their fleet and extend the lifecycle of their vehicles. Two key aspects of Metro’s success are the close monitoring of each bus in the fleet and the proactive replacement of key components instead of waiting for them to fail. Fueled by real-time data and powered by the industry’s most powerful algorithms, Metro Transit’s solution includes an alert system set up to pre-alert before faults, enabling them to predict when components will fail. The same data can be examined from a macro perspective to show patterns from a fleet-wide view.”

Results

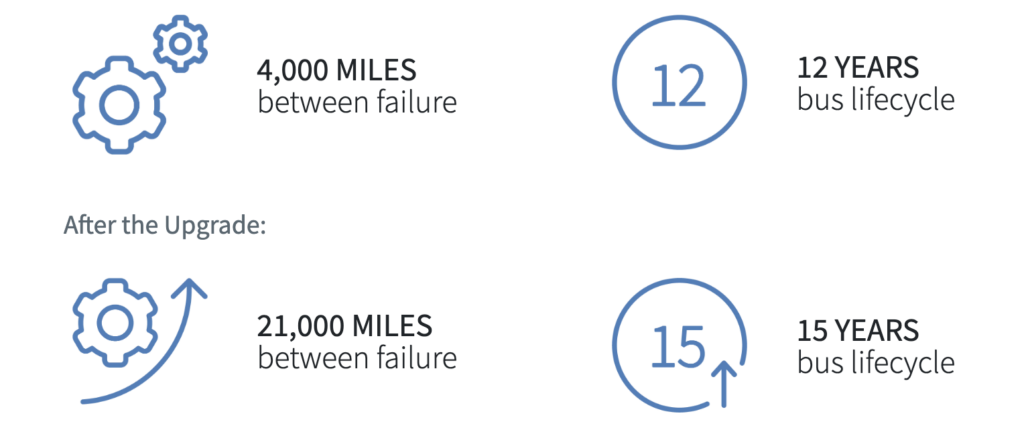

Metro Transit adopted a predictive replacement maintenance program. By implementing Vontas’ Vehicle Intelligence solution, they are able to use business intelligence data gathered from the vehicles and the controller area network to proactively manage their fleet and extend the lifecycle of their vehicles. Two key aspects of Metro’s success are the close monitoring of each bus in the fleet and the proactive replacement of key components instead of waiting for them to fail. Fueled by real-time data and powered by the industry’s most powerful algorithms, Metro Transit’s solution includes an alert system set up to pre-alert before faults, enabling them to predict when components will fail. The same data can be examined from a macro perspective to show patterns from a fleet-wide view. Metro Transit – St. Louis transitioned from a break fix maintenance model to a predictive replacement maintenance model resulting in $2.4 million in annual savings on their operational budget.